ATTENTION Cummins Suppliers, PDC, Distributors, and OEM Plants

This article is being published to raise awareness and as reminder of a Global Regulation for use of Solid Wood Packaging Materials. Many countries have put quarantine regulations in place to protect their native forests from the introduction of wood pests. In order to prevent the proliferation of differing import regulations, the International Plant Protection Convention (IPPC), part of the Food and Agriculture Organization (FAO) of the United Nations, has issued ISPM 15 (International Standards for Phytosanitary Measures) "Guidelines for Regulating Wood Packaging Material in International Trade". This regulation has been in effect since 2004. Cummins Inc. requires that ALL export solid wood packaging materials comply with this regulation regardless of what country it is being sent to. In addition, ALL shipments using solid wood packaging material being shipped to any of our Parts Distribution Centers or Master PDC's must comply with this regulation as it may be shipped in your provided packaging anywhere in the world.

Cummins has received many recent notices of violations to this regulation from some of the Customs Inspection and Quarantine Services. We need to be sure ALL of our Suppliers, PDC's, Distributors, and OEM Plants are in alignment and complying with this regulation. It is our Global Packaging Standard requirement and it is a global regulation. The risks for non-compliance include, but are not limited to, the following if not met immediately:

- Result in quarantine and/or remediation by the Customs Quarantine and Inspection Services (QIS)

- Cummins' customs status being negatively impacted

- Delay in delivering of the freight on time

- Potential production stoppage

- A Supplier Corrective Action Request (SCAR) being issued to the Supplier for non-compliance to the Cummins Global Packaging Standards and this regulation

- Supplier being debited for these delays and expenses incurred by Cummins

- Key requirements of ISPM15 are:

- IPSM 15 applies only to solid wood timber products

- Solid wood thinner than 6 mm being exempt of this regulation

- Manufactured or engineered wood products are exempt from this regulation

For example such as:

- Plywood

- Oriented strand board (OSB)

- Laminated Veneered Lumber (LVL)

- Laminated Strand Lumber (LSL)

- Pressed Wood

- Treatment of the solid wood timber packaging materials by approved measures, which include:

- Heat treatment (HT) to a core temperature of 56°C for at least 30 minutes.

- Methyl bromide (MB) depending on concentration, duration and temperature.

- If applicable, DB (debarked)

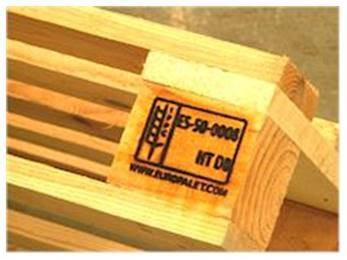

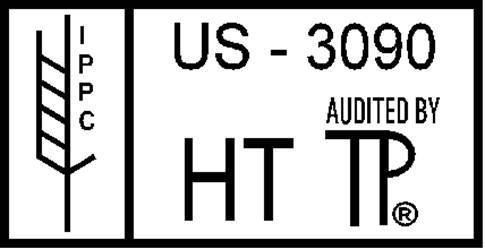

- Permanent and clearly legible marking of the packaging must be provided on two opposite sides of the package. See examples below:

- Dunnage requires a separate stamp DUN_HT on at least two sides of each piece. Dunnage is defined as a piece of wood used for blocking, bracing or support and it is not viewed as an integral part of the wood packaging system

- Additionally, pieces intended for use as dunnage must be marked every two feet, so that any cutting of the longer piece into shorter pieces will ensure that the mark is present on each of the shorter pieces. In the case of dunnage shorter than 2 feet, each piece must still have the mark present. See example of a DUN mark below:

Copy this link below into your internet browser to access the ISPM15 Standard Document for more details: http://ispm15.com/ISPM15_Revised_2009.pdf

If you have any questions about this regulation, please contact your wood packaging providers. PDC’s and OEM Plants should contact their respective Global Packaging Council Member or their local Packaging Representative.